Page 1 of 1

Upgraded Oil Pump

Posted: Tue Jan 01, 2019 11:02 pm

by fredeuce

Obvious change is the pickup. I must say the original is a very small item and this modification suggests the original is restrictive.

Anyone able to comment on these upgraded pumps?

https://www.ebay.com.au/itm/Uprated-Dai ... ctupt=true

Re: Upgraded Oil Pump

Posted: Wed Jan 02, 2019 6:10 am

by Ian Slade

When you check the seller it appears to be Russ Carpenter's business, one does wonder what the OEM pump could produce with a stronger relief spring?

Re: Upgraded Oil Pump

Posted: Wed Jan 02, 2019 8:36 am

by fredeuce

Ian,

As it happens I have been conducting some experiments to determine just that.

With the presence of the orifice in the relief valve plunger and cranking by hand all of the oil simply ran out of the orifice. That said I have observed that my engine always took a considerable time to generate oil pressure on the gauge ( mechanical capillary type) after which I would turn on the ignition.

(as my car is a competition vehicle I have separated the starter motor circuit from the ignition circuit and will only turn on the spark once the pressure is up)

My engine is also equipped with a remote oil filter and related hoses. I can only assume that a quantity of this oil is draining back through the orifice in the relief valve.

My first experiment was to silver solder the orifice and then test the pressure at hand cranking speeds. Immediately the pump produced 40 psi at which point the relief valve clearly had opened.

Second experiment was to pack the relief valve spring and determine the effect of that step. Previous discussions on this topic have indicated that a 3/8" spacer can be inserted. I made a 3/8" spacer and inserted it and tested once again. This time the pressure at the same speed was 60 psi or thereabouts.

Given the low cranking speeds I thought that was very good and decided to try a spacer slightly shorter. This one came in at 8.5 mm. Inserted and tested once again. This time it came in at around 55 psi.

I think I will install the pump in the engine and conduct a further test in due course. However I think is a big step forward and am confident my concerns should now be sorted.

I will also look at putting a larger pick up on whilst I am at it.

Re: Upgraded Oil Pump

Posted: Wed Jan 02, 2019 9:04 am

by Ian Slade

I would suggest a stronger spring rather than packing, packing reduces the spring travel which may in certain cases reduce the relief flow. The pump is designed to relief at about 50psi, it may well be that is all the engine requires when within design tolerances, increasing the pressure could result in wear on the softer metals and can in extreme cases damage the pump drive. The engine was designed in the late 50's and at that time most engines oil pressure was set to bypass, there were certain Ford engines that suffered catastrophic failure due to the oil pump drive failing in the 60's and 70's

Re: Upgraded Oil Pump

Posted: Wed Jan 02, 2019 10:52 pm

by Chris_R

You should remember that the pressure that you are reading is primarily the resistance to the flow of the oil from out of the bearings. Oil from the pump is forced into the small clearance between the crankshaft journal and the bearings and it leaks out of the sides down into the sump. This is by design and is how heat in the bearings is carried away. A heavy grade oil will flow slowly when cold and will take more time to fill up the spaces than a lighter weight oil and the pressure will rise more slowly. A heavier grade of oil will also have higher internal friction and generate more internal heat.

Also important to note that it is not the pressure that you are reading that supports the crankshaft and maintains the gap between the journal and the bearings. Instantaneous pressures in this region can reach 6,000psi or more. As the oil enters the bearing gap it is dragged around by the rotation of the crankshaft and forms a wedge at the smallest point of clearance and it is this wedge that supports the crankshaft and prevents metal to metal contact.

For normal driving you don't need to see more than about 10psi per 1,000 rpm. Increasing the point at which the pressure relief valve operates won't increase the flow of oil into the bearings, you can only get a certain amount through a given space. All it will do is suck energy from the engine and increase the strain on components such as the pump itself as Ian has suggested.

Re: Upgraded Oil Pump

Posted: Tue Jan 08, 2019 11:53 pm

by fredeuce

After some further research on the old website and particularly the learning shared by Russ Carpenter I have decided to keep the pump with the blocked orifice in the relief valve and a packing behind the spring of 7mm .This generates an opening pressure on the bench of 55psi. Once I receive my new cam I will conduct and in car test of the pump to determine what cranking pressures are generated and make any adjustments before final assembly.

This engine should see max rpm of approximately 7000rpm . Duration will be 237 deg @ .050 and around 0.434 valve" lift .

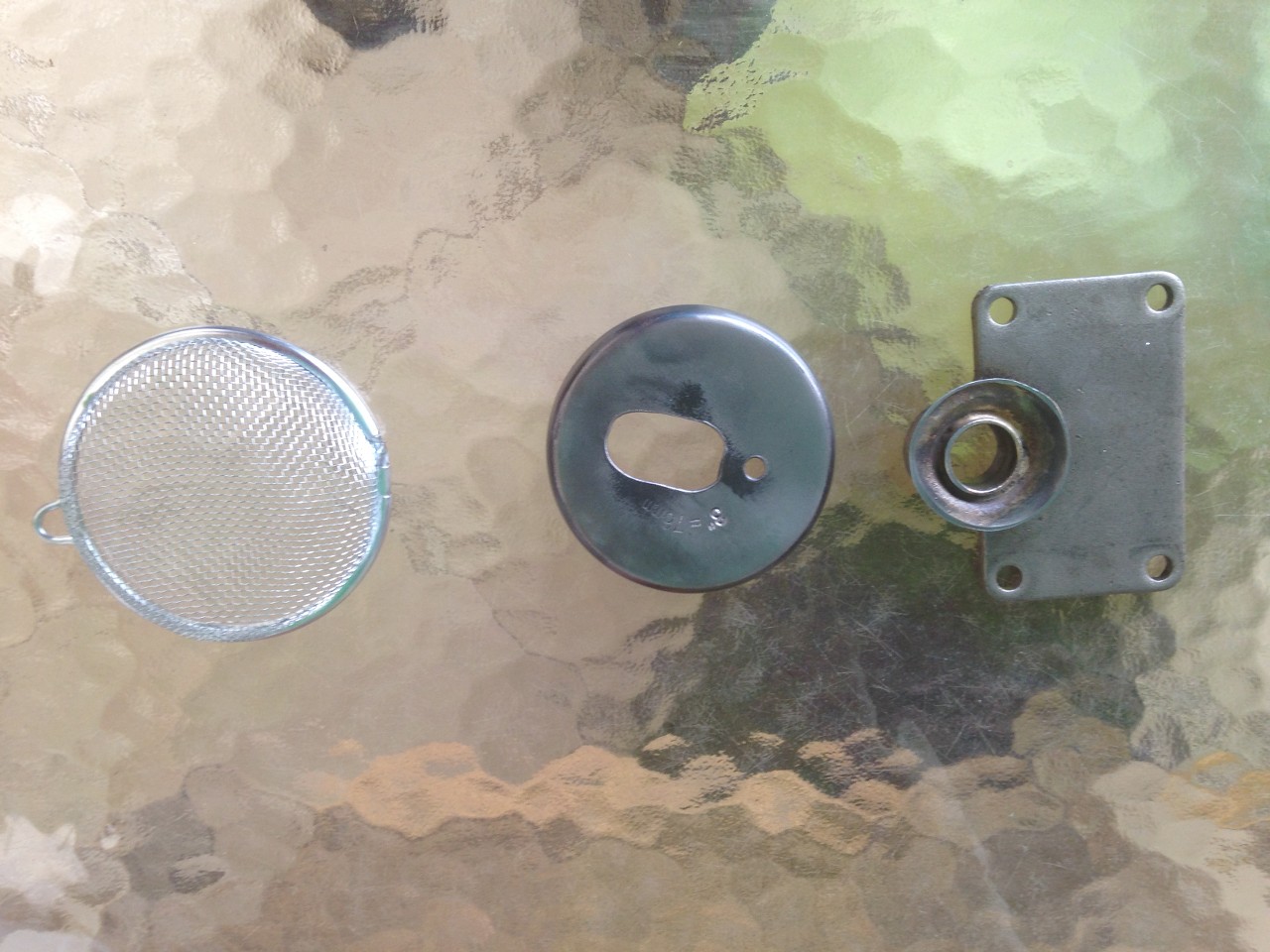

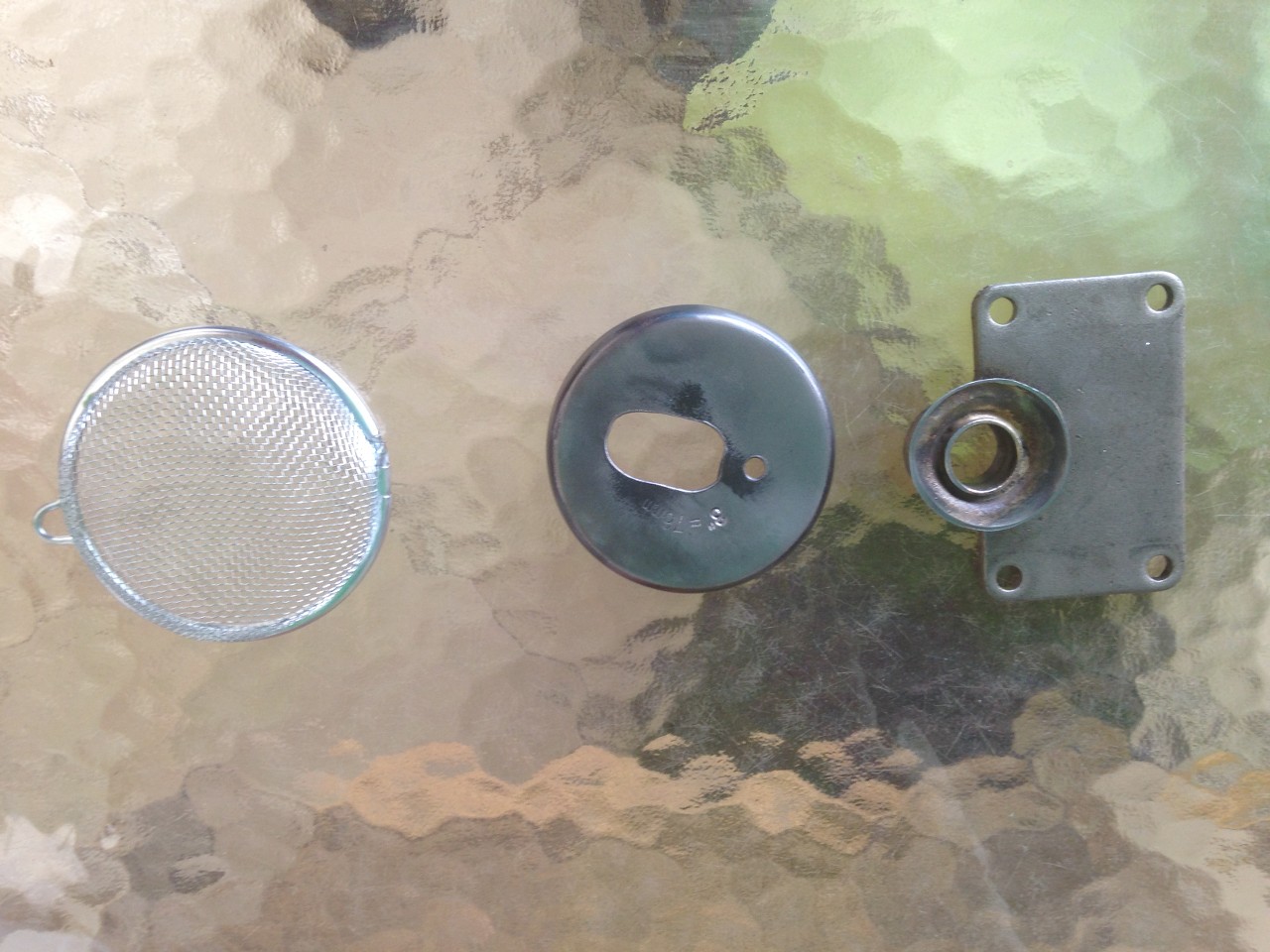

I have also upgraded the pickup. See photos attached.

Re: Upgraded Oil Pump

Posted: Wed Jan 09, 2019 9:11 am

by Sonus

Is your engine an SP250 version Fred? Looks like it from the pick up. I have had an uprated pump built by Andrew and Russ Carpenter that has a shortened saloon pick up to work with my future 1" sectioned oil pan/sump. Reason for sectioning it is to be able to lower the engine further down into the chassis in my TVR to gain better clearance to the bonnet (higher ilet manifold system), to lower the center of gravity and to level out the propshaft angles of my very short (355mm) propshaft.

Re: Upgraded Oil Pump

Posted: Wed Jan 09, 2019 10:03 am

by fredeuce

My engine is a 2.5 Sedan version not the SP250.

That said the sump on my engine was modified by a previous owner no doubt for ground clearance reasons. The result is that the deeper , rear portion which is inclined and not flat has been modified to flat. See pictures attached.

This resulted in the original pump having the pickup bell and connector pipe shortened. Knowing the depth restrictions I had to come up with something to suit and the previous picture is the result.